Category: Nestable Crate

What is Nestable Plastic Crates

Nestable plastic crates are space-saving storage and transport containers designed to nest inside each other when empty, reducing volume by up to 70%. Unlike stackable-only models, these plastic pallet crates are ideal for high-turnover operations where return logistics, storage optimization, and labor efficiency are key. We offer both ventilated nestable plastic crates for airflow-sensitive goods, and solid nestable plastic crates for applications requiring dust and impact protection. All models are built from HDPE/PP for long-term use, compatible with reusable plastic pallets and crates in automated or manual systems.

Advantages of Our Nestable Crates

Built for Reverse Logistics Efficiency

Our nestable plastic crates nest up to 70% when empty, drastically reducing return trip volume and cutting transport costs in closed-loop supply chains.

Available in Ventilated or Solid Models

Whether you need airflow to maintain product freshness or full enclosure to prevent dust contamination, we manufacture both ventilated and solid nestable plastic crates to match your operational environment.

Reinforced Load Zones for Stable Stacking

The crate base and rim structure are reinforced to handle dynamic stacking, even during forklift braking or transit vibration—preventing tilt, shift, or crate deformation.

Easy-To-Clean Surfaces for Reuse Cycles

Whether ventilated or solid, all crate surfaces are engineered with cleanable materials and minimal dirt-trap zones—supporting efficient rinsing, draining, and hygienic turnover in food-grade environments.

Made From Durable, Recyclable PP/HDPE

We use virgin or blended food-grade PP and HDPE for high impact resistance, chemical tolerance, and consistent long-cycle durability—even in cold storage or humid conditions.

Fully Compatible With Standard Pallet Systems

All dimensions conform to plastic pallet crates and dolly standards, ensuring easy integration into your warehouse flow, whether manually handled or on conveyor systems.

Application of Nestable Crates

Nestable plastic crates are widely adopted across industries that demand space-saving logistics, hygienic handling, and reliable backhaul efficiency. Their intelligent nesting design supports seamless transitions between storage, transport, and point-of-use operations.

| Application Area | Use Case | Description |

Agriculture & Produce Handling | Field Harvest Collection | Ventilated nestable crates ensure airflow and protect fruits or vegetables during field-to-packing transfer. |

| Packhouse Sorting Lines | Easily nestable crates reduce clutter and streamline movement across fast-paced packing stations. | |

| Cold Chain Storage | Nestable formats minimize idle storage footprint inside temperature-controlled units. | |

| Return Transport to Farms | Crates nest tightly after delivery, cutting costs on return trips to rural production sites. | |

Retail & Supermarket Distribution | In-Store Backroom Storage | Crates efficiently nest when not in use, keeping store backrooms organized and accessible. |

| Shelf Replenishment Logistics | Stackable during transport, nestable on return, supporting fast and clean restocking cycles. | |

| Seasonal Product Swaps | Ideal for rotating high-turnover SKUs with minimal manual handling. | |

| Reusable Packaging for Store Transfers | Replaces one-time boxes with reusable plastic crates for inter-store logistics. | |

Food Processing & Cold Chain Logistics | Meat and Seafood Handling Zones | Solid nestable plastic crates reduce contamination risk in chilled environments. |

| Bakery and Pastry Distribution | Ventilated models maintain freshness while reducing unloading time. | |

| Temperature-Sensitive Transit | Nestable crates with perforations enhance air circulation across stacked cargo. | |

| Sanitary Storage Between Shifts | Washable crates ensure clean nesting between production runs. | |

General Industry & Warehousing | Component Replenishment Lines | Nestable crates move small parts efficiently between work cells and assembly zones. |

| Manual Order Picking Zones | Lightweight nesting crates reduce fatigue during repetitive warehouse tasks. | |

| Returns Processing Stations | Crates nest when idle, freeing space around high-volume return workflows. | |

| Spare Parts Distribution Networks | Durable plastic crates protect small mechanical parts in shared transport lanes. |

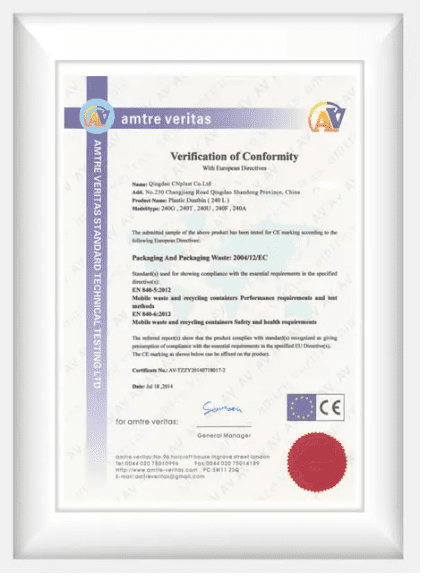

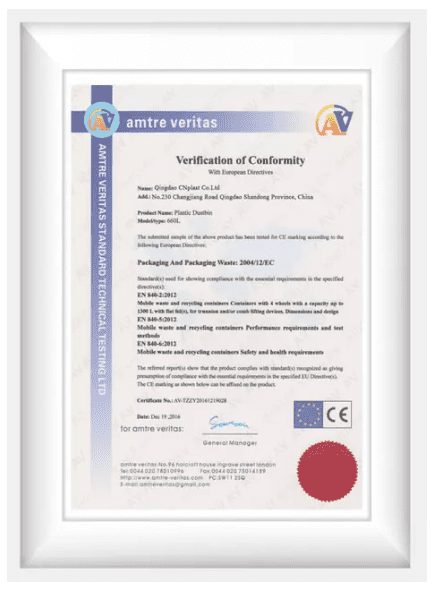

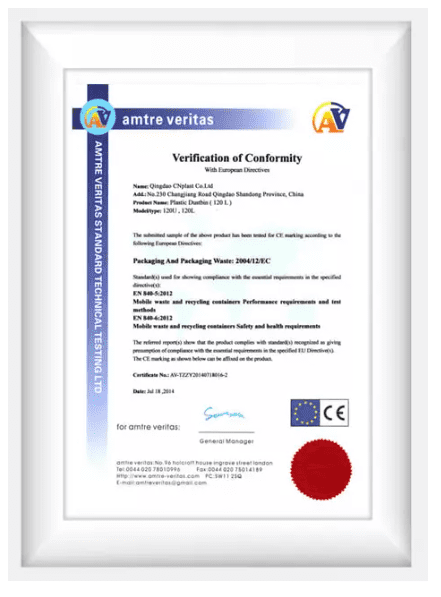

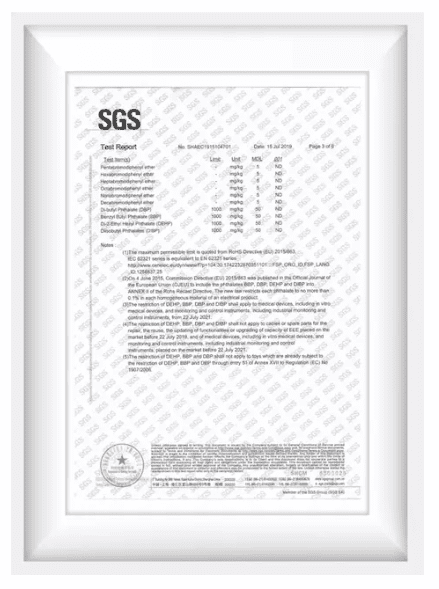

Global Standards, Certified Quality

Our plastic crates, boxes, and pallets comply with internationally recognized certifications including ISO 9001, FDA, RoHS, REACH, and SGS, ensuring quality, safety, and regulatory compliance for global trade.